Home Page » Technology

technology

Carbon Fiber

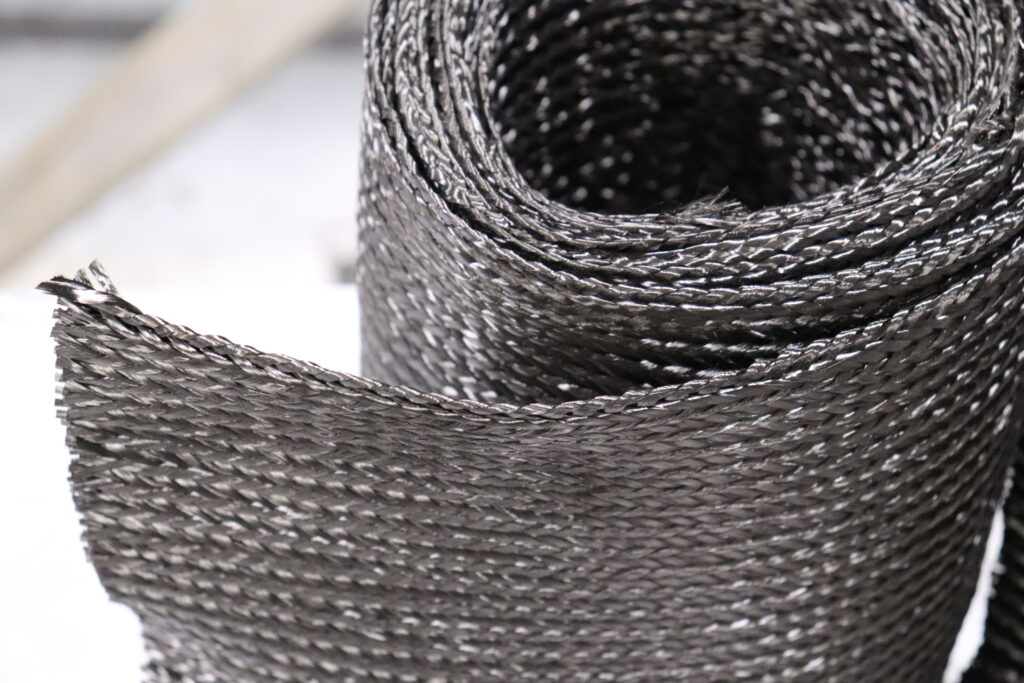

Triaxially braided

Braided carbon fiber holds significant importance for two key reasons. Firstly, unlike our competitors who employ a cloth layup approach, it remains unaffected by delamination. This unique attribute ensures prolonged durability of our bows even within the demanding environment of a buncher.

Secondly, the braided carbon fiber maintains its structural integrity consistently across the bow’s width and profile. This integrity, preserved due to the absence of cutting, establishes the utmost strength configuration for carbon fiber components.

improving bow life

SAMP WIDE

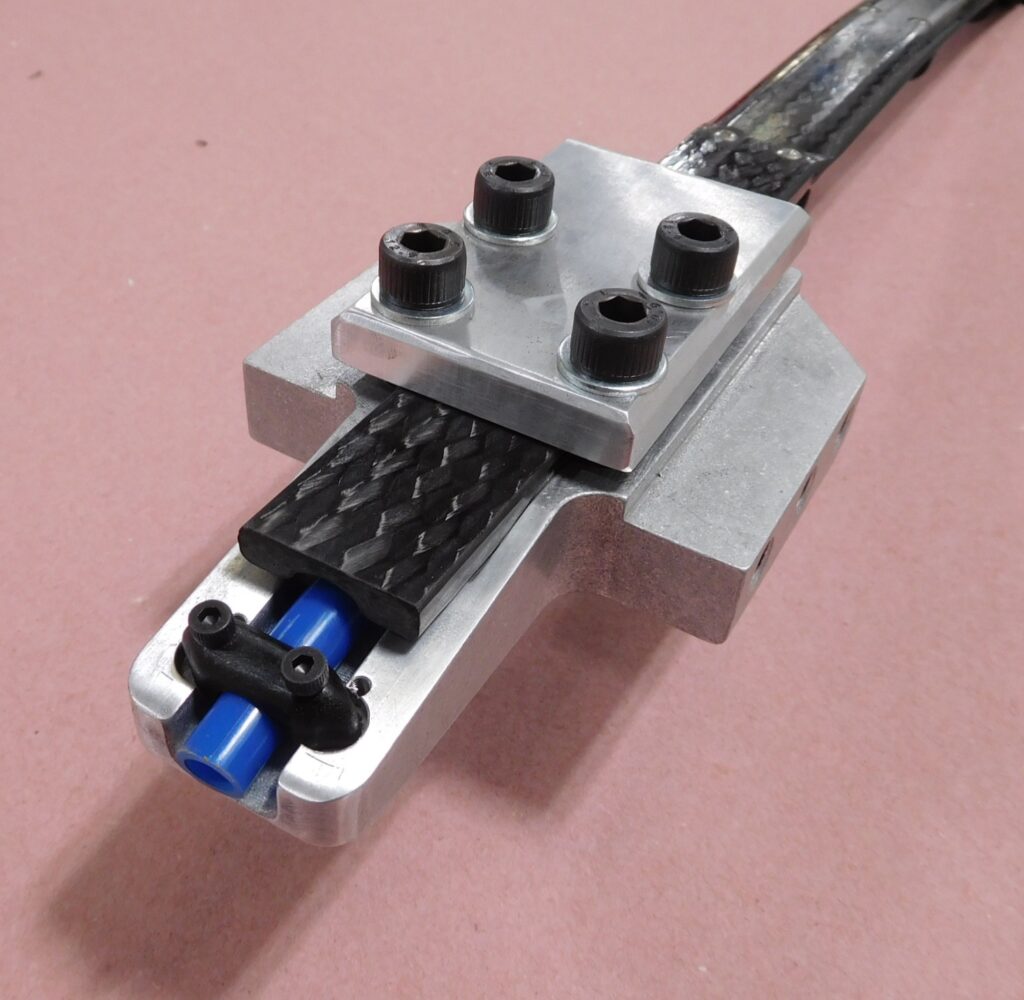

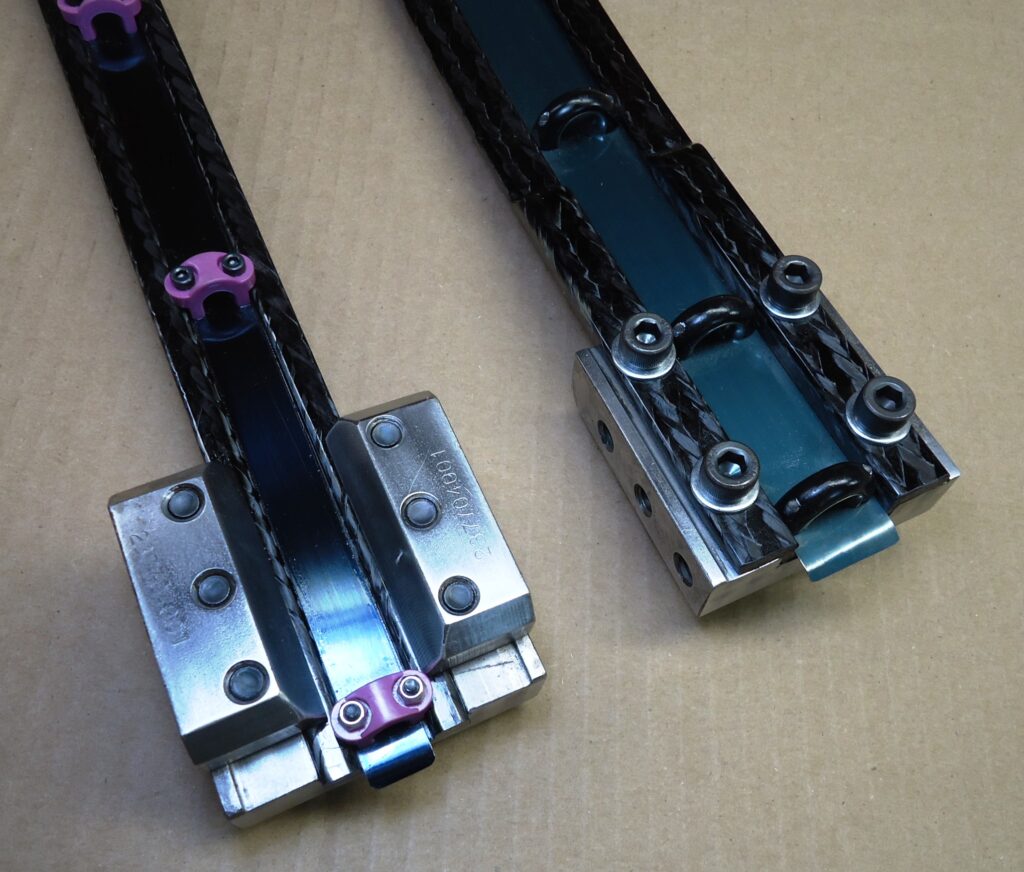

SAMP WIDE buncher bows were designed to improve the OEM mounting system. Our new design securely bolts to the mount block, resulting in increased bow life and decreased failures at the interface. Each buncher bow is reinforced with steel rope along the bow’s edge, safeguarding against wire strike damage. Available across various machine sizes and guide options, SAMP WIDE bows feature slip-in wear plates for streamlined operator maintenance. Elevate the performance of your SAMP bunching machine.

new applications

customization

While available in a range of standard configurations, we also tailor buncher bows to the specifications of our customers, recognizing that their unique wire requirements drive the need for precision engineering. For those pursuing specialized wire types, our ability to customize buncher bows, ensures optimal performance and wire quality. Moreover, we understand that energy efficiency and operational ease are paramount.